PRODUCTS

Product Series

Drilling Automated Elevators and Clamping Equipment

Only three oil channels are needed for the top drive to realize the opening and closing, flipping and signal transmission of the elevator.

Patented design, developed for the trend of electric-driven drilling and workover rigs, uses imported electric cylinders to achieve actions such as lifting card switching, flipping and following movements.

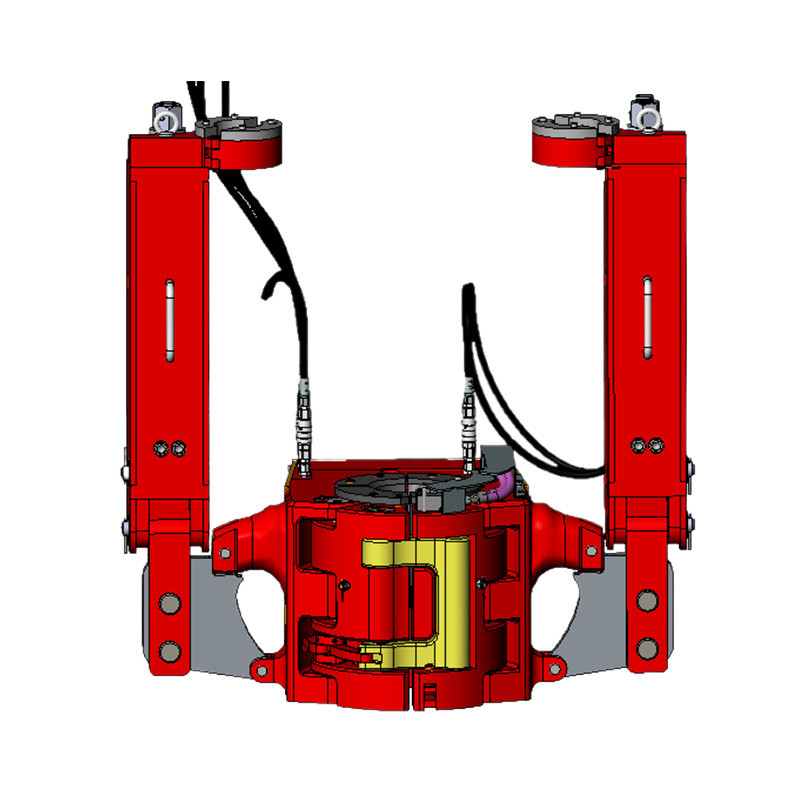

Cylinder Type Hydraulic Elevator

Cylinder type hydraulic elevator, used in conjunction with the new workover rig automation

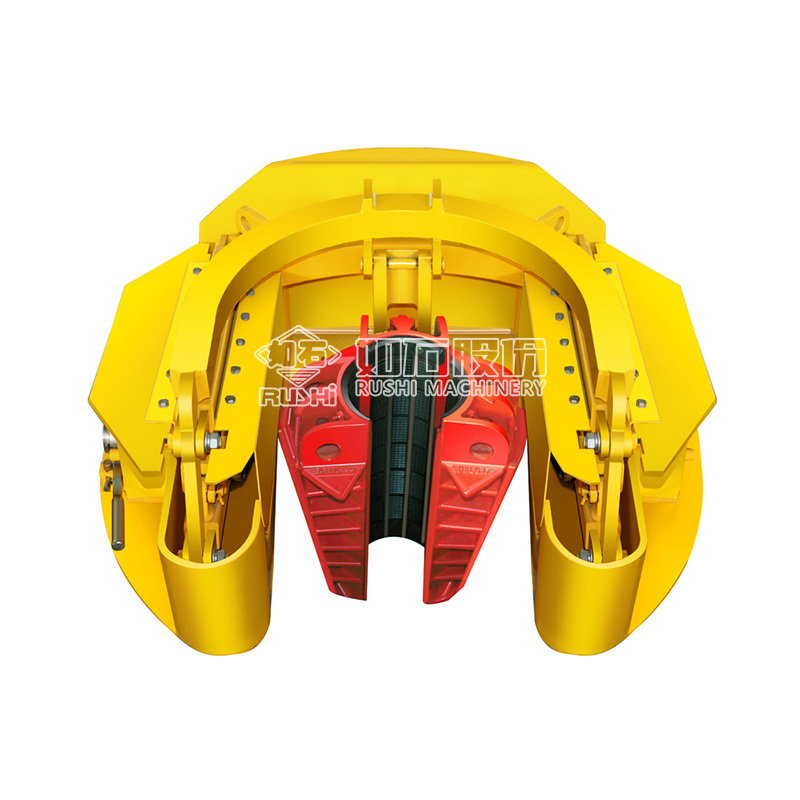

QD Pneumatic Casing Elevator/Chuck

QD pneumatic casing elevator/slip is suitable for casings of 60-622mm (23/8-241/2in). Pneumatic operation, labor-saving and safe. It is an ideal tool for casing operation. Designed and manufactured according to API Spec 8C "Specification for Drilling and Oil Production Lifting Equipment".

WQ type pneumatic drill pipe slips have the dual functions of automatically holding the drill pipe during the oil drilling operation and automatically scraping the mud from the drill pipe during the drilling operation. It is an ideal wellhead mechanized tool and is suitable for use on various types of drilling rig rotary tables. It has the characteristics of easy installation, simple operation, safety and reliability, high degree of automation, and improved drilling speed. The technical indicators meet SY5049.

Pneumatic and hydraulic workover chucks

Pneumatic and hydraulic chucks are mainly used to hold drill pipes and tubing in oil and gas well repair operations. The products are designed and manufactured in accordance with the requirements of API Spec 7K "Specification for Drilling and Well Repair Equipment". All chucks can be operated pneumatically or hydraulically, which can effectively reduce the labor intensity of workers and improve work efficiency.

DWJ-178/250 power slips are a hydraulic remote-controlled mechanized tool used to hold and suspend the drill string in the well during the tripping process. Different sizes of drill strings require different slips, and the applicable drill pipe range is 60mm-178mm.